Most businesses bleed time and money quietly. Let’s find out where yours is leaking.

When business owners think about automation, the first question is usually, “How much does it cost?” That’s a fair question. But here’s a better one:

What is manual work already costing you?

You might not see it as a line item on your balance sheet, but the impact is real. Small inefficiencies like delays, double-entry, or forgotten follow-ups add up fast. Over time, they waste hours, frustrate customers, and chip away at your profit margin.

This article breaks down the hidden cost of doing things by hand. You’ll see how much time and money manual processes are draining from your business and what you can do to take control.

The Five Hidden Cost Centers of Manual Work

1. Errors and Rework

Mistakes happen when people are tired, distracted, or overloaded. A mistyped email, a skipped step in a process, or an outdated spreadsheet can result in hours of backtracking, or worse, lost business.

If a team of five each spends just one hour per week fixing avoidable mistakes, that’s more than 250 hours per year. At $30 per hour, that’s $7,500 in wasted labor and that doesn’t include the cost of unhappy customers or lost opportunities.

2. Delays and Bottlenecks

Manual systems depend on people being present, alert, and available. When someone is out sick or buried in other tasks, work stops. Follow-ups are delayed. Customers wait longer. Payments slow down.

Delays cost more than just time. They break momentum, reduce customer satisfaction, and lead to missed revenue. Automation keeps work moving, even when no one is watching the clock.

3. Labor Inefficiency and Overhead

You’re paying smart people to do repetitive tasks. That’s a problem. Copying data between platforms, sending reminder emails, and running reports manually might feel like “work,” but it’s not valuable work.

A single automation tool can often replace many hours of repetitive effort. And the more you grow, the worse manual inefficiencies get.

4. Missed Revenue and Growth Opportunities

Every hour spent on manual tasks is an hour not spent on sales, strategy, or customer retention. Leads get cold. Quotes get delayed. Upsells are never offered. It’s not just about saving time. It’s about making room for growth.

Automation doesn’t just reduce cost. It unlocks potential revenue your team is too busy to chase.

5. Inconsistent Customer Experience

Manual workflows vary depending on who’s handling them. One client gets a fast, friendly follow-up. Another gets forgotten for three days. That kind of inconsistency undermines trust and makes it harder to scale.

Automation delivers consistency. Every client gets the same prompt reply, the same quality service, and the same dependable experience no matter who’s on shift.

Each of these cost centers may seem small on their own. But when combined, they create a constant drain on your business. The longer you wait to automate, the more you pay to stay where you are.

The Multiplier Effect: What It All Adds Up To

Small inefficiencies feel harmless when you look at them in isolation. But multiply them across your entire team, every day, all year, and the financial impact becomes impossible to ignore.

Let’s walk through a simple example.

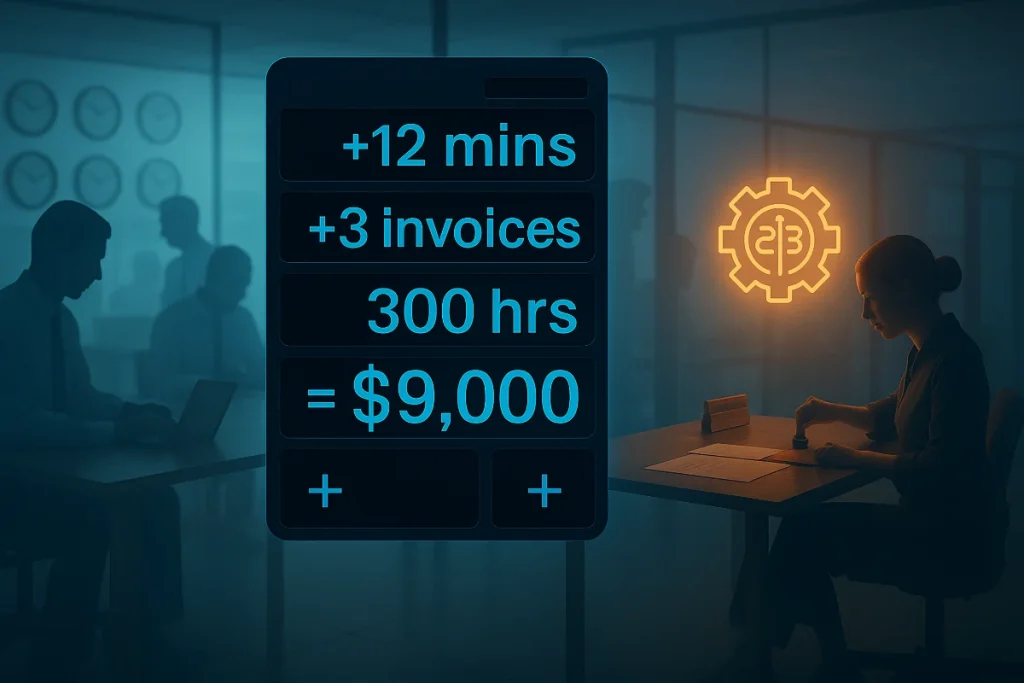

Scenario: Manual Invoice Processing

- Task: Creating, sending, and logging customer invoices

- Time required: 12 minutes per invoice

- Frequency: 3 invoices per day

- Employees affected: 2 team members

- Total time: 72 minutes per day

- Weekly total: 6 hours

- Annual time spent: Approximately 300 hours

- Average hourly wage: $30

- Annual cost: $9,000

And that’s just one task.

Now apply this logic across your business.

- Five daily tasks per employee

- Each task taking 5 to 15 minutes

- A team of five to ten people

The hidden labor cost can easily exceed $50,000 per year. That figure does not include the opportunity cost of tasks your team is missing, such as following up on unpaid invoices, improving cash flow, or serving customers more effectively.

Why This Matters

Manual work rarely gets tracked or measured. It’s invisible in the moment but expensive over time. The more your business grows, the more time you lose to repetitive processes unless you address them proactively.

Automation is not about solving a problem once. It’s about removing a recurring problem entirely so you stop paying for it every day.

Manual vs. Automated Workflow Comparison

To truly understand the cost of manual work, it helps to see the difference side by side. Let’s take a common business process and compare what it looks like when handled manually versus through automation.

Scenario: Appointment Scheduling and Confirmation

Whether you’re booking service calls, consultations, or client meetings, scheduling is a task that touches multiple team members and impacts the customer experience.

Manual Workflow

- A team member receives a request by phone or email

- They reply to suggest available times

- The customer responds with preferences

- The scheduler updates the calendar and sends a confirmation

- On the day of the appointment, a reminder is sent manually

- If the customer cancels or reschedules, the process starts again

Total time spent per appointment: 10 to 15 minutes

Risk factors: Missed messages, double bookings, late reminders, customer frustration

Automated Workflow

- Customer books a time directly through an online scheduler

- Calendar updates in real time across all relevant systems

- Confirmation is sent automatically

- Reminder is delivered by text or email without team involvement

- Cancellations or changes update the calendar and notify all parties instantly

Total time spent per appointment: Zero

Result: Fewer errors, faster turnaround, improved customer experience

The Takeaway

The manual approach may feel manageable when volume is low. But as your business grows, these repetitive tasks consume more of your team’s time and increase the chances of mistakes. Automation keeps things moving, even during off hours, and removes the guesswork from simple but important processes.

Common Objections, Answered

Even when business owners understand the costs of manual work, hesitation around automation is still common. Below are the most frequent objections we hear, along with direct, practical responses.

“We don’t have time to automate.”

If your team is already stretched thin, that’s the exact reason to automate. Every day you spend doing repetitive tasks manually is another day you lose time you could be investing elsewhere. Most automations take just hours to set up but save hundreds of hours per year.

“My team is already good at this.”

That may be true. But skill is not the issue. Value is. Your team should be spending their time on work that grows the business, not on tasks a system can complete instantly and accurately. Good employees become even more valuable when freed from repetitive processes.

“We can’t afford automation right now.”

Manual work is costing you far more than you think. Automating even one or two key workflows can recover thousands of dollars per year. Many automation tools cost less than a single payroll hour each week. In most cases, the payback period is measured in weeks, not months.

“We’re too small for this.”

If you’re a small team, you feel every inefficiency more acutely. Lost time, missed follow-ups, and manual errors hit harder when you have fewer resources. Automation is not just for large companies. It is a force multiplier for lean teams that want to scale without overhiring.

“We’ve tried automation before, and it didn’t work.”

Poor implementation is not the same as poor technology. The key is to match the right tools to the right processes. When automation is approached strategically, with the right partner and plan, it works. We’ve seen it save time, cut costs, and improve customer satisfaction in businesses just like yours.

Why It Matters More Than Ever

Manual work has always been inefficient. But in today’s business climate, it’s more than just inefficient, it’s dangerous to your bottom line.

Margins are tighter. Customer expectations are higher. Labor is more expensive and harder to find. Business owners are being asked to do more with less, and the cracks are starting to show.

Three Trends That Make Manual Work a Bigger Problem in 2025

1. Labor costs continue to rise

Wages have increased across the board. Every hour your team spends on repetitive work is more expensive than it was a year ago. Automation doesn’t replace people. It reduces unnecessary labor and allows you to get more value from every person you employ.

2. Customers expect fast, flawless service

Response time matters more than ever. If you take too long to follow up, quote, invoice, or confirm an appointment, you’re giving customers a reason to look elsewhere. Automation ensures that nothing slips, even when your team is busy.

3. Your competitors are getting smarter

Automation tools have become easier to use, more powerful, and more affordable. Businesses that adopt them now gain a competitive edge. If you wait, you’ll be playing catch-up while others move faster and deliver more value with fewer resources.

The Real Risk Isn’t Automating. It’s Standing Still

Sticking with manual processes may feel familiar, but it’s becoming more expensive every day. You’re losing time, missing opportunities, and falling behind the companies that have already embraced smarter systems.

Now is the time to shift. Automating even one or two workflows can free up hours per week, reduce errors, and create consistency your customers can count on.

Let’s Crunch the Numbers Together

By now, you’ve seen how manual work creates hidden costs, missed opportunities, and operational drag. The question is no longer if it’s costing you, it’s how much.

Every repetitive process in your business represents a chance to save time, reduce mistakes, and put your team’s talent to better use. Whether it’s invoicing, follow-ups, scheduling, or customer communication, automation can turn those slow, manual tasks into fast, reliable systems that work in the background.

What You’ll Get From a Workflow Assessment

We offer a no-pressure consultation where we walk through your current operations and highlight where automation can save time and money.

Here’s what we’ll help you identify:

- Tasks that are costing you the most in wasted labor

- Workflows that are vulnerable to errors or delays

- Opportunities to improve consistency and customer experience

- The estimated financial impact of making a change

Ready to See the Numbers for Yourself?

You do not need to commit to anything today. Just a conversation to uncover what’s already costing you more than it should.

Let’s crunch the numbers together and find your savings.

No pitch. No pressure.

Just a real conversation about what automation could do for your business.